Have you ever wondered what that shiny, raised print on your t-shirt is called? It's called plastisol, a type of ink that is commonly used in screen printing.

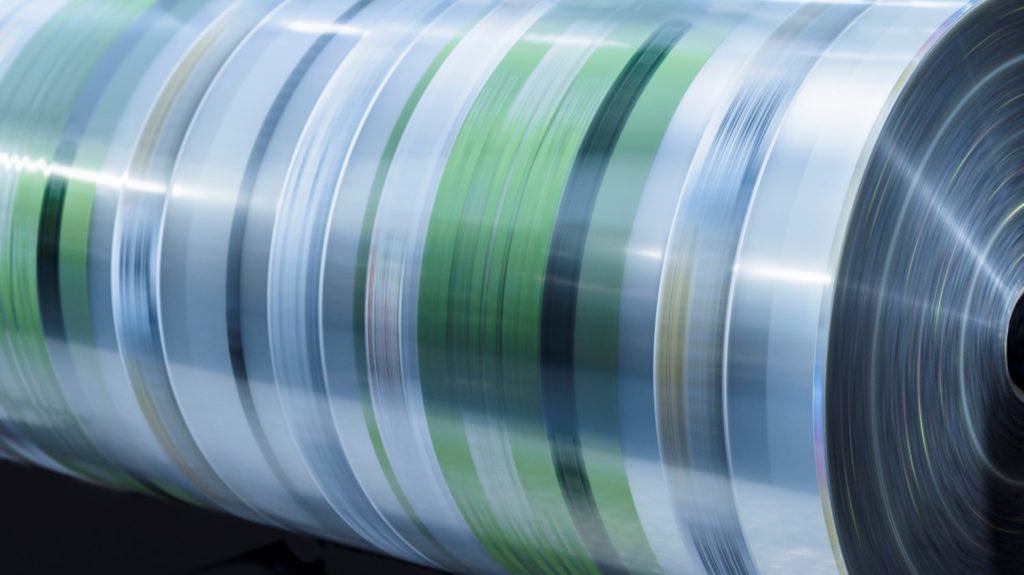

Plastisol ink is made up of PVC particles suspended in a liquid plasticizer. When the ink is heated, the plasticizer evaporates and the PVC particles fuse together, creating a durable and flexible print. This process is called curing.

Plastisol ink is popular in the garment industry because it can be used on a variety of fabrics, including cotton, polyester, and blends. It also produces bright and vibrant colors that are long-lasting and resistant to fading.

However, plastisol ink does have some drawbacks. It can feel heavy and stiff on the fabric, and it's not as environmentally friendly as other types of ink. Some companies are now using water-based or discharge inks, which are more eco-friendly and produce a softer feel on the fabric.

When shopping for printed shirts, it's important to consider the type of ink used and its impact on the environment. Look for companies that use eco-friendly inks and sustainable production practices.

In conclusion, plastisol ink is the plastic print on shirts that is created through a process of heating and curing. While it produces bright and durable prints, it's important to consider the environmental impact and alternative ink options.