Mechanical joints play a pivotal role in various industries, providing the means to connect and secure components together. Understanding the different types of joint mechanisms is essential for engineers and professionals seeking optimal solutions for their projects. In this blog post, we will embark on a comprehensive exploration of mechanical joints, delving into their various types and highlighting their unique characteristics. By gaining insights into these diverse joint mechanisms, readers can make informed decisions when selecting the most suitable option for their specific applications.

- Welded Joints:

Welded joints are widely recognized for their exceptional strength and durability. This type of joint involves melting and fusing the materials of the components being joined, creating a solid and continuous bond. Welded joints are commonly used in structural applications, such as construction and automotive industries, where high load-bearing capacity is required. However, it is important to consider factors such as material compatibility, welding techniques, and potential distortions during the welding process. - Bolted Joints:

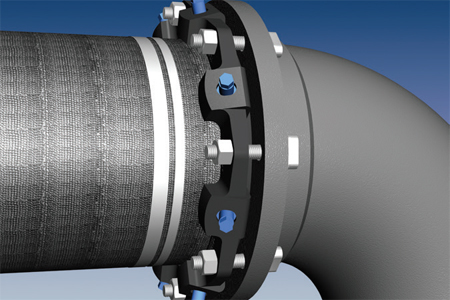

Bolted joints offer versatility and ease of assembly, making them popular in a wide range of applications. This type of joint involves using bolts, nuts, and washers to secure components together. Bolted joints can be easily disassembled and reassembled, allowing for maintenance and repairs. They are suitable for applications that require adjustable or detachable connections. However, it is crucial to consider factors such as bolt size, torque specifications, and potential for loosening under dynamic loads. - Riveted Joints:

Riveted joints have a long history of use in industries such as aerospace and shipbuilding. This type of joint involves using rivets to connect components together. Rivets are inserted into pre-drilled holes and then deformed to create a permanent connection. Riveted joints offer excellent strength and resistance to vibration, making them suitable for applications that require robust and reliable connections. However, the riveting process can be time-consuming and may require specialized equipment. - Adhesive Joints:

Adhesive joints utilize adhesives or bonding agents to bond components together. This type of joint offers advantages such as uniform stress distribution, corrosion resistance, and the ability to join dissimilar materials. Adhesive joints are commonly used in industries such as aerospace, automotive, and electronics. However, factors such as surface preparation, adhesive selection, and curing time must be carefully considered to ensure optimal bond strength and longevity. - Snap-fit Joints:

Snap-fit joints rely on the flexibility and elasticity of materials to create secure connections. This type of joint involves designing components with interlocking features that can be easily snapped together. Snap-fit joints are commonly used in consumer products, such as plastic enclosures and packaging. They offer advantages such as rapid assembly, cost-effectiveness, and ease of disassembly. However, snap-fit joints may have limitations in terms of load-bearing capacity and long-term durability.

Conclusion:

The world of mechanical joints is vast and diverse, offering a multitude of options for connecting components in various industries. By exploring the different types of joint mechanisms, including welded joints, bolted joints, riveted joints, adhesive joints, and snap-fit joints, engineers and professionals can make informed decisions when selecting the most suitable option for their specific applications. Each type of joint has its unique characteristics, advantages, and limitations, and understanding these nuances is crucial for achieving optimal performance, reliability, and efficiency in engineering projects.