In the world of plastic extrusion, high performance isn't just about the extruder itself—it’s also about the reliability and quality of the auxiliary parts that work alongside it. Whether you're producing composite materials, recycling PET, or manufacturing high-precision sheet lines, choosing the right extruder auxiliary parts is key to maximizing output and ensuring long-term durability.

At JiaXin Mechanical Manufacture, we specialize in the design, manufacturing, and turnkey delivery of extrusion and forming machinery for the plastics industry. With deep experience in composite and recycling process lines, including twin-screw and single-screw extruders, sheet production lines, and PET recycling systems, we understand how critical auxiliary components are to a smooth and efficient operation.

Why Auxiliary Parts Matter

Auxiliary parts may not always be the focus of your equipment investment, but they play essential roles in material handling, cooling, feeding, and downstream processing. Poor-quality or mismatched auxiliary systems can result in:

-

Inconsistent product quality

-

Increased maintenance needs

-

Reduced throughput

-

Higher energy consumption

-

Shortened equipment lifespan

That’s why selecting the right auxiliary parts—designed to work in harmony with your main extruder—is crucial.

Key Factors to Consider

Here are the most important factors to evaluate when selecting auxiliary parts for your extrusion line:

1. Compatibility with Your Extruder Type

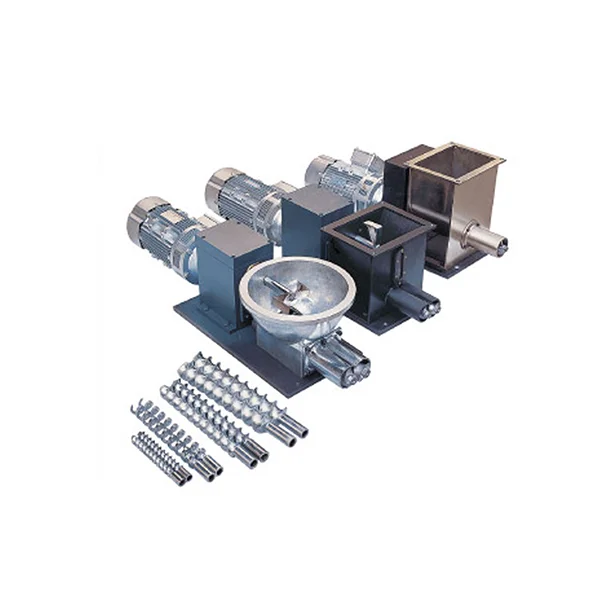

Whether you’re using a twin-screw extruder for compounding or a single-screw extruder for recycling, auxiliary parts must be engineered to match the characteristics of your system. For instance, feeders and side stuffers used in twin-screw extrusion lines must be robust enough to handle high torque and temperature variability.

2. Material Throughput Requirements

Your choice of feeders, dryers, and pelletizers should reflect your desired output. Oversized or undersized components can lead to bottlenecks or underutilization of your main extruder’s capacity. At JiaXin, our auxiliary systems are designed to integrate seamlessly with high-capacity lines, including PET recycling production lines.

3. Durability and Build Quality

Look for auxiliary parts built from high-grade steel and corrosion-resistant materials, especially if you’re working with recycled or abrasive materials. Long service life and low maintenance needs are essential for reducing downtime and total cost of ownership.

4. Automation and Control Integration

Modern extrusion systems benefit greatly from smart controls and automation. Choose auxiliary parts with advanced PLC interfaces that can integrate into your existing control systems. This ensures better synchronization, real-time monitoring, and optimized production cycles.

5. Energy Efficiency

Supporting components like chillers, vacuum systems, and drying units should be energy efficient. Over time, energy-saving designs can significantly lower operating costs while contributing to your sustainability goals.

JiaXin’s Turnkey Advantage

Choosing the right auxiliary parts can be complex, especially when you're trying to upgrade or customize a line for a new product. That’s why JiaXin Mechanical Manufacture offers complete turnkey solutions—we don’t just provide machinery, we deliver fully engineered systems designed to meet your exact production needs.

From design and installation to commissioning and training, our team works closely with each customer to select the ideal combination of extruders and auxiliary equipment. Whether you’re building a composite production line or optimizing a PET sheet recycling process, JiaXin ensures every component works together for maximum efficiency and lifespan.

Final Thoughts

Auxiliary parts are the unsung heroes of extrusion systems. By carefully selecting components that match your processing needs, production goals, and extruder configuration, you can significantly boost output and extend the service life of your machinery.

If you're looking for expert guidance and reliable equipment tailored for the plastic extrusion industry, JiaXin Mechanical Manufacture is here to help. Let’s build a better, more durable production line—together.

www.tcextruder.com

JiaXin Mechanical Manufacture CO., Ltd